Natural super basics [Coffee Fanatic Hitomi 's Deep Coffee World No. 9]

Hitomi Ryo" />

Hitomi Ryo" /> Hello! I'm Coffee Fanatic Hitomi !

In the last article , we finished explaining all about the washed type, so from now on I would like to talk about the non-washed type.

In the last article , we finished explaining all about the washed type, so from now on I would like to talk about the non-washed type.

Natural is harder to select than washed.

Well, it is the oldest and most primitive production process, and I think the original commercial process was in Yemen. The harvested fruit is dried as is, threshed, and the raw beans are extracted.

...It's so easy!! (*'▽')

We have previously mentioned that washed leather is ranked higher than natural leather , and this is because from the perspective of production and processing, it is easy to distinguish between superior and inferior quality.

In the case of the washed method, the pulp is removed first, so if there is something wrong with the parchment coffee inside, it can be immediately identified. Furthermore, it can be graded by separating the coffee by gravity using a waterway or siphon.

In the case of the non-washed (Natural) method, the flesh is not removed, so even if a fruit (such as a cherry) appears fine at first glance, it is not possible to tell if the inside is made of underripe parchment or has been eaten by insects.

...It's so easy!! (*'▽')

We have previously mentioned that washed leather is ranked higher than natural leather , and this is because from the perspective of production and processing, it is easy to distinguish between superior and inferior quality.

In the case of the washed method, the pulp is removed first, so if there is something wrong with the parchment coffee inside, it can be immediately identified. Furthermore, it can be graded by separating the coffee by gravity using a waterway or siphon.

In the case of the non-washed (Natural) method, the flesh is not removed, so even if a fruit (such as a cherry) appears fine at first glance, it is not possible to tell if the inside is made of underripe parchment or has been eaten by insects.

As the drying process progresses, both green and red fruits turn Shin black, making it impossible to tell the ripeness of the fruit. Furthermore, the long dry period increases the risk of bacteria activating and foreign matter becoming mixed in due to moisture from rain and other sources.

In the case of natural coffee like this, the only way to extract good quality green beans is to improve the precision of the dry mill just before export, rather than relying on the precision of the wet mill.

In the case of natural coffee like this, the only way to extract good quality green beans is to improve the precision of the dry mill just before export, rather than relying on the precision of the wet mill.

These are the ones rejected by the dry mill. (They were originally specialty specs so they're pretty clean.)

So, in terms of quality, natural coffee is a little difficult to export. Coffee is a valuable source of foreign currency income for producing countries, so it is natural that they must export high quality export standards, so coffee with a quality risk is for domestic consumption, and high-risk natural coffee is avoided. Therefore, basically, with the exception of Brazil, there are no export standards for natural coffee in coffee producing countries in Central and South America.

So, in terms of quality, natural coffee is a little difficult to export. Coffee is a valuable source of foreign currency income for producing countries, so it is natural that they must export high quality export standards, so coffee with a quality risk is for domestic consumption, and high-risk natural coffee is avoided. Therefore, basically, with the exception of Brazil, there are no export standards for natural coffee in coffee producing countries in Central and South America.

It seems that with the rise of specialty coffee, the production of natural coffee for export has become more active in the specialty industry over the past 15 years or so.

Now let's take a look at the natural production process!

Now let's take a look at the natural production process!

The very basics of non-washable (Natural)

Although the production process is simple, there are surprisingly many variations. Here's a look at the general process.

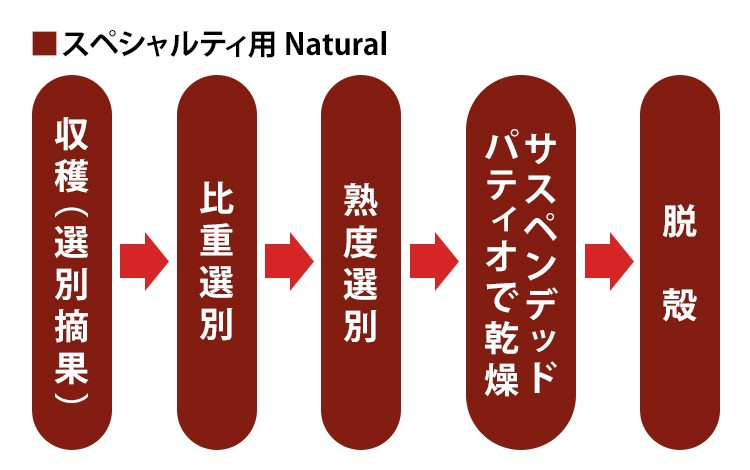

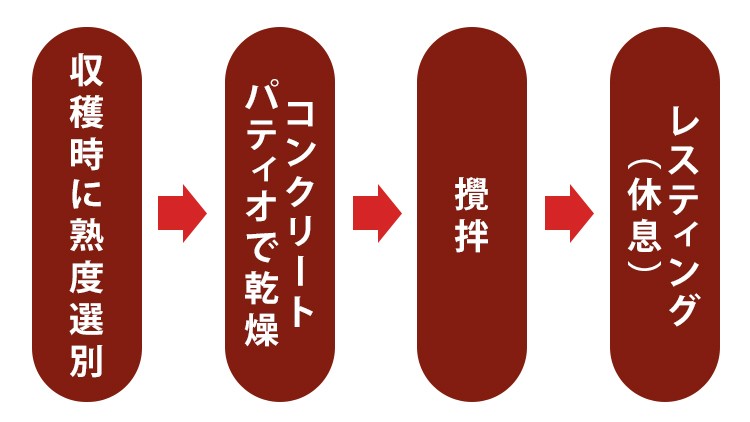

Whereas for Specialties it looks like this:

Let's take a look at them in order.

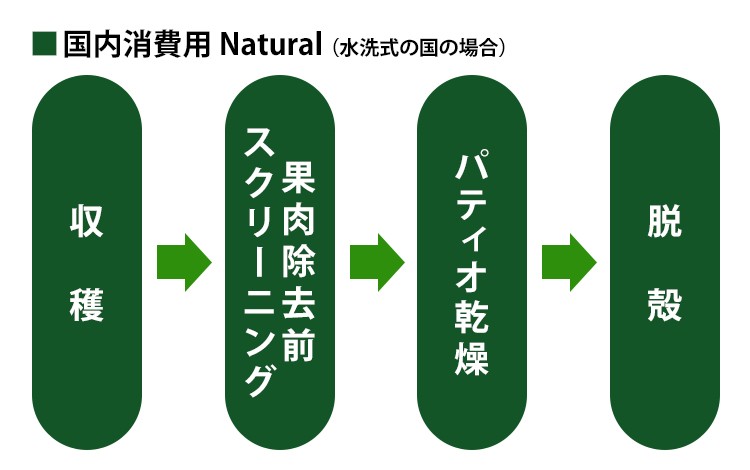

[For domestic consumption]

This is the most disappointing grade. In countries where the washing method is the norm, this grade is made into natural coffee from coffee that is not worthy of washing. During screening before the pulp removal process, fruits that are too small or hard fruits (Boia) that have shrunk due to being too dry are removed, and these are the fruits that are targeted here. Fruits that were not peeled by the pulp removal machine are also passed through this line.

These unfortunate fruits are left to dry on concrete patios and are threshed without any special treatment. The coffee produced in this way has a strong astringent taste (super dry), a bitter taste, an earthy taste, and in some cases a chemical smell of phenol. ...It is undrinkable as it is, so in Costa Rica, for example, they use special kilns that can add sugar and roast the coffee (I wonder if it doesn't burn (;・∀・)?), which makes the coffee forcibly sweet and sends it for domestic distribution. ...In a sense, it can be said to be the most combative coffee (death).

These unfortunate fruits are left to dry on concrete patios and are threshed without any special treatment. The coffee produced in this way has a strong astringent taste (super dry), a bitter taste, an earthy taste, and in some cases a chemical smell of phenol. ...It is undrinkable as it is, so in Costa Rica, for example, they use special kilns that can add sugar and roast the coffee (I wonder if it doesn't burn (;・∀・)?), which makes the coffee forcibly sweet and sends it for domestic distribution. ...In a sense, it can be said to be the most combative coffee (death).

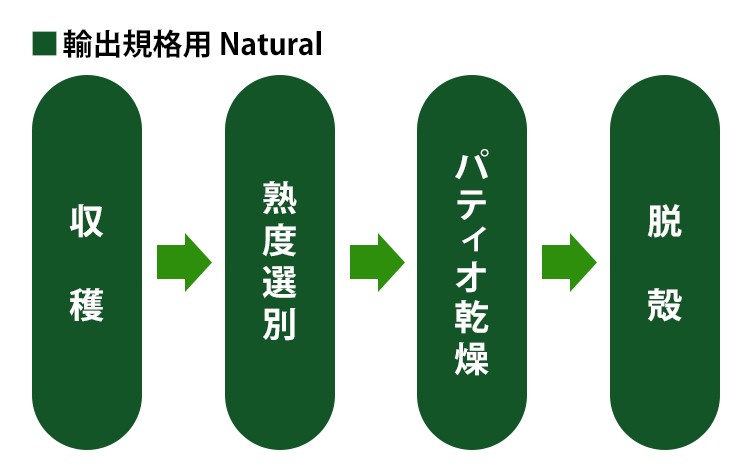

[For export standards]

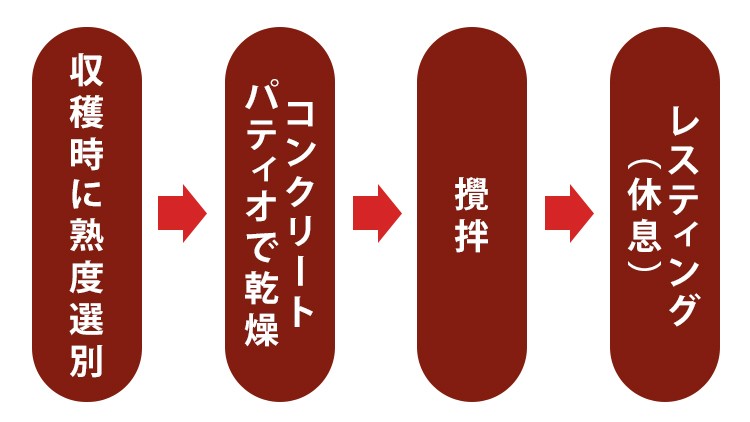

This is what they call a normal natural product. Well, it's a process that is carried out in Brazil, Ethiopia, etc. The process is not that complicated, but you can see a little care put into it at key points. The basic flow is something like this.

The production process takes about 30 days. This is because the moisture content is high when the flesh is still attached and it is difficult to dry. In Brazil, the ripeness is adjusted by adjusting the output of the harvesting machine and using a color-difference sorting machine. In Ethiopia, farmers hand-pick the cherries, and then hand-pick them again at the collection point to sort them by ripeness.

In Brazil, the dried vegetables are spread out on concrete patios. In Ethiopia, they are dried on raised platforms called African beds or sun-spended patios. They are stirred at set intervals to ensure they dry evenly, and if it rains, they are covered with black plastic sheets to prevent them from getting wet.

Once drying is complete, the grain is put into grain bags and stored in a silo or warehouse. In Brazil, wooden silos (which are easy to control humidity) are often built, and the environment is often set up for a short rest.

After this, the next step is the dry mill process.

Basically, these traditional, authentic natural wines tend to have a stronger sweetness and body, but they do not have a fruity or fermented smell. On the contrary, we are careful not to let these flavors stick to the wine. I mentioned this in a previous article.

....

Is this basically like this?

That was the basic natural thing.

Next time, I'd like to talk about naturals in specialty areas!

Well, good day everyone.

The production process takes about 30 days. This is because the moisture content is high when the flesh is still attached and it is difficult to dry. In Brazil, the ripeness is adjusted by adjusting the output of the harvesting machine and using a color-difference sorting machine. In Ethiopia, farmers hand-pick the cherries, and then hand-pick them again at the collection point to sort them by ripeness.

In Brazil, the dried vegetables are spread out on concrete patios. In Ethiopia, they are dried on raised platforms called African beds or sun-spended patios. They are stirred at set intervals to ensure they dry evenly, and if it rains, they are covered with black plastic sheets to prevent them from getting wet.

Once drying is complete, the grain is put into grain bags and stored in a silo or warehouse. In Brazil, wooden silos (which are easy to control humidity) are often built, and the environment is often set up for a short rest.

After this, the next step is the dry mill process.

Basically, these traditional, authentic natural wines tend to have a stronger sweetness and body, but they do not have a fruity or fermented smell. On the contrary, we are careful not to let these flavors stick to the wine. I mentioned this in a previous article.

....

Is this basically like this?

That was the basic natural thing.

Next time, I'd like to talk about naturals in specialty areas!

Well, good day everyone.

Fanatic Hitomi

If you want to enjoy coffee more deeply

" CROWD ROASTER APP"

Manabu at CROWD ROASTER LOUNGE

・Push notifications for article updates・Full of original articles exclusive to CROWD ROASTER

・Direct links to detailed information about green beans and roasters

App-only features

- Choose green beans and roasters to create and participate in roasting events・CROWD ROASTER SHOP: Everything from beans to equipment is readily available

・GPS-linked coffee map function

Ryo Mikami

After graduating from Manabu , he worked at Starbucks for some reason, which led him to discover the potential of coffee. After many twists and turns, he joined a specialty coffee trading company. He was enlightened to the way of the fanatic, and is now involved in a wide range of work from commodities to specialties, including market analysis, visiting coffee producing areas, judging competitions, coaching competitions, extraction, roasting, and equipment proposals. He is also an advisor for CROWD ROASTER .

Free washed fermentation process [Coffee Fanatic Hitomi 's Deep Coffee World Part 6]

Basic flow of flushing method [Coffee Fanatic Hitomi 's Deep Coffee World Part 4]

What is production processing? [Coffee Fanatic Hitomi 's Deep Coffee World Part 1]

What is infused coffee? [Coffee Fanatic Hitomi 's Deep Coffee World No. 18]

What is the Costa Rican Anaerobic Honey Process? [Coffee Fanatic Hitomi 's Deep Coffee World No. 17]

What is the difference between yellow, gold, and black? Costa Rican Honey Process [Coffee Fanatic Hitomi 's Deep Coffee World No. 16]