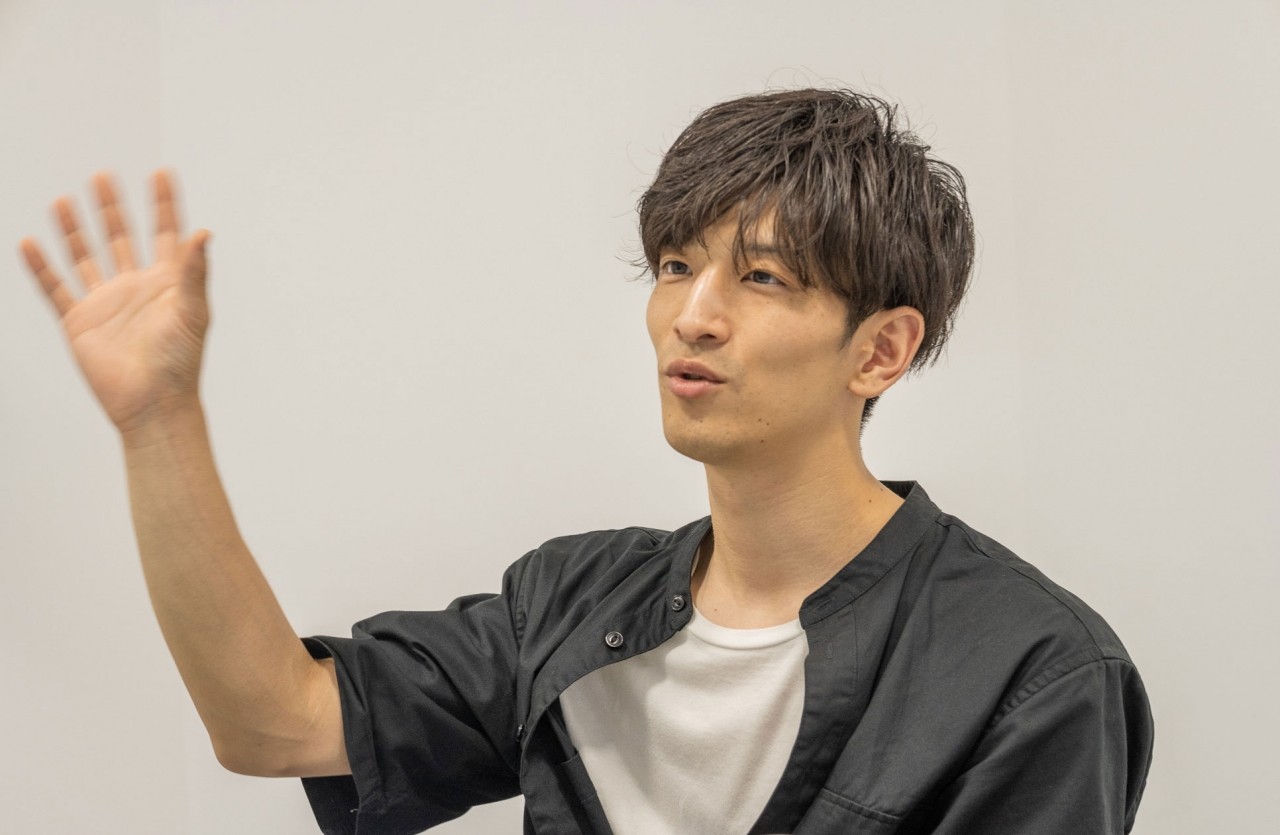

Special interview with R&D ESPRESSO LAB representative Kokoro Honda

This time, the grinder used at CROWD ROASTER , the EK43, was starting to malfunction, so we invited Honda Shin, representative of R&D ESPRESSO LAB, a group of coffee mechanics who are expanding their activities to focus on maintaining espresso-related machines and grinders, to come in and talk to us while we maintained the grinder.

We interviewed Honda about his own career and the company.

We interviewed Honda about his own career and the company.

We'll share some interesting stories about how he decided to start a company specializing in machine maintenance and what kind of work he does on a daily basis.

(Interviewer: CROWD ROASTER Hiroto Usukura )

Focus on the machine, not the barista

Usukura : What made you get into the coffee industry?

Honda: It all started when I started working at Starbucks in Tokyo while I was a student at University of Manabu .

When I was working there part-time, it was the heyday of specialty coffee, about 10 years ago, and Blue Bottle Coffee had just opened in Japan.

During my time at Manabu , I had the opportunity to travel abroad to countries like the US, Canada, India, and Australia. I saw the coffee scene there and thought it was cool, so I became hooked on specialty coffee.

Even back then, I wanted to have an espresso machine at home and a MAZZER grinder, but since it wasn't available in Japan, I researched how to get one and ended up buying it myself, as I was so passionate about coffee.

Usukura : Was there anything that came in handy from your exposure to overseas countries during your time as a student Manabu ?

Honda-san: Maybe it's because I was originally in the Management Manabu , but when I went overseas I would observe what kind of market it was in that country.

Seeing a market like Japan where chain stores are strong and a market like Australia where people drink coffee at their favorite coffee shop every day, I realized that this was a cultural difference.

From then on, I began to constantly question many things, and my experience abroad has led to the way I work today.

Honda: It all started when I started working at Starbucks in Tokyo while I was a student at University of Manabu .

When I was working there part-time, it was the heyday of specialty coffee, about 10 years ago, and Blue Bottle Coffee had just opened in Japan.

During my time at Manabu , I had the opportunity to travel abroad to countries like the US, Canada, India, and Australia. I saw the coffee scene there and thought it was cool, so I became hooked on specialty coffee.

Even back then, I wanted to have an espresso machine at home and a MAZZER grinder, but since it wasn't available in Japan, I researched how to get one and ended up buying it myself, as I was so passionate about coffee.

Usukura : Was there anything that came in handy from your exposure to overseas countries during your time as a student Manabu ?

Honda-san: Maybe it's because I was originally in the Management Manabu , but when I went overseas I would observe what kind of market it was in that country.

Seeing a market like Japan where chain stores are strong and a market like Australia where people drink coffee at their favorite coffee shop every day, I realized that this was a cultural difference.

From then on, I began to constantly question many things, and my experience abroad has led to the way I work today.

Usukura : What is your background in the coffee industry?

Honda: After that, when I was looking for a job, I took a job at Lucky Coffee Machine, where I maintained the machines for about three years.

After that, I worked in sales at DCS for about a year, and that's where I am today.

Usukura : I think there were other options besides using a machine, such as barista or roasting, so why did you choose a machine?

Honda: When I was looking for a job about 10 years ago, roasting wasn't really a focus.

At that time, NOZY COFFEE was at its peak, and they elevated the status of the vague profession of coffee barista.

However, I thought I could become a barista later.

So, what else is there besides being a barista? Ever since I was a student Manabu , I had been watching the coffee scene overseas and had a strong desire to go abroad someday.

Honda: After that, when I was looking for a job, I took a job at Lucky Coffee Machine, where I maintained the machines for about three years.

After that, I worked in sales at DCS for about a year, and that's where I am today.

Usukura : I think there were other options besides using a machine, such as barista or roasting, so why did you choose a machine?

Honda: When I was looking for a job about 10 years ago, roasting wasn't really a focus.

At that time, NOZY COFFEE was at its peak, and they elevated the status of the vague profession of coffee barista.

However, I thought I could become a barista later.

So, what else is there besides being a barista? Ever since I was a student Manabu , I had been watching the coffee scene overseas and had a strong desire to go abroad someday.

I vaguely thought that if I could go abroad, I would be able to do so as long as I had English and some other competitive skills.

That's when I started to focus on "machines."

Usukura : Did you start your current company immediately after leaving DCS?

Honda-san: The launch of my company was a series of miracles (laughs).

When I was at Lucky Coffee Machine, I originally joined the company because I loved specialty coffee, but I couldn't find a place where I could use that knowledge.

Lucky mainly sells commodity coffee, such as coffee from convenience stores and chain stores.

I realized that this was not what I had hoped for, so I joined DCS as a sales representative.

At that time, the customer base changed, I was able to interact with a variety of people, and I became immersed in the world of specialty coffee once again.

However, as I continued working, I learned about the Japanese coffee industry and felt a gap between it and overseas.

So I decided to go abroad, something I had always dreamed of.

Just as I was making various preparations to go abroad, the coronavirus came and I was no longer able to go.

At the time, I was honestly in despair...

So we wondered what to do and that's how the company started.

Giving up on going overseas, he became an authorized dealer of roasting machines

Usukura : What prompted you to start a company from there?

Honda: At first, I only did small jobs, helping people in need around me and doing work for acquaintances when they asked me to.

Honda: At first, I only did small jobs, helping people in need around me and doing work for acquaintances when they asked me to.

However, I felt that I wouldn't be able to scale if I continued like this, and when I thought about what kind of work I could do other than machine-related work, I decided to try roasting.

The first roasting machine I bought there was "aillio," which I now handle as an authorized dealer.

Usukura : Why did you focus on "aillio"?

Honda: No one else had one, and an acquaintance of mine was using aillio. When I tried his coffee, I thought it would be great, so I bought it.

Once we started using it, we were inundated with inquiries from all kinds of people, and we stopped being a roasting company and shifted to being an agency.

From there, we started getting more offers for repairs and distributorships, and we settled on the company's current style.

Usukura : So, did the company start by selling "aillio"?

Honda-san: This is true of course for "aillio" as well, but whenever we went to do maintenance, customers would ask us all sorts of questions, such as "Do you have a tool like this?", and that's how we started bringing in products from overseas.

Usukura : When bringing in products from overseas, such as "aillio," do you contact the manufacturer directly?

Honda-san: Of course, I inquire directly. People overseas are very clear about their opinions, and they usually decide quickly whether something is good or bad (laughs).

It seemed like "aillio" wasn't doing much at the time, so we were able to come to an agreement quickly.

Usukura : You've been incredibly proactive, especially when you started your company (laughs). Is there anything you value in your work?

Honda-san: The "R&D" in my company's name, "R&D ESPRESSO LAB," stands for "Research & Development." I chose it to express my desire to innovate, not just stay in the present, by encouraging improvements and making things better.

Our theme was not to improve the machine, but to make the coffee even more delicious.

So, we would like our customers to come and ask us anything about coffee, regardless of the machine.

So, our number one priority is to solve the coffee-related problems our customers have.

Responding flexibly to requests from cafes and baristas

Usukura : What kind of people do you usually approach for work these days?

Honda: We get a lot of inquiries from cafes that mainly serve specialty coffee, but we've also started getting inquiries from a variety of places, including Italian restaurants and freelance baristas.

Furthermore, we have recently been fortunate to receive more requests from barista champions.

Usukura : What do you think makes you different from other companies?

Honda: I feel like there aren't many coffee makers that operate flexibly.

I think the biggest difference between us and other agencies is that we have coffee machine technicians at the top, and because of that, I think our decision-making speed is overwhelmingly different compared to other manufacturers.

Usukura : Please tell us what your goals are for the future, Honda-san.

Honda: Japanese engineers tend not to disclose much information, and when experienced engineers leave, maintenance often becomes impossible.

In order to change this situation, I would like to share the skills I have as a technical trainer.

As our company name suggests, we want to continue to be positioned to solve problems.

Honda: We get a lot of inquiries from cafes that mainly serve specialty coffee, but we've also started getting inquiries from a variety of places, including Italian restaurants and freelance baristas.

Furthermore, we have recently been fortunate to receive more requests from barista champions.

Usukura : What do you think makes you different from other companies?

Honda: I feel like there aren't many coffee makers that operate flexibly.

I think the biggest difference between us and other agencies is that we have coffee machine technicians at the top, and because of that, I think our decision-making speed is overwhelmingly different compared to other manufacturers.

Usukura : Please tell us what your goals are for the future, Honda-san.

Honda: Japanese engineers tend not to disclose much information, and when experienced engineers leave, maintenance often becomes impossible.

In order to change this situation, I would like to share the skills I have as a technical trainer.

As our company name suggests, we want to continue to be positioned to solve problems.

Honda is always searching for what the problem is and how to solve it.

Through this interview, I realized that it is precisely because of Honda's personality that so many coffee shop owners come to him for advice about machines.

Honda also performed maintenance on the EK43, which is the main topic of this article.

The grind was surprisingly quiet and smooth, and the entire CROWD ROASTER team was amazed.

We also asked about easy maintenance that can be done at home, so we would like to introduce more detailed maintenance methods in the future.

Through this interview, I realized that it is precisely because of Honda's personality that so many coffee shop owners come to him for advice about machines.

Honda also performed maintenance on the EK43, which is the main topic of this article.

The grind was surprisingly quiet and smooth, and the entire CROWD ROASTER team was amazed.

We also asked about easy maintenance that can be done at home, so we would like to introduce more detailed maintenance methods in the future.

Stay tuned!

If you want to enjoy coffee more deeply

" CROWD ROASTER APP"

Manabu at CROWD ROASTER LOUNGE

・Push notifications for article updates・Full of original articles exclusive to CROWD ROASTER

・Direct links to detailed information about green beans and roasters

App-only features

- Choose green beans and roasters to create and participate in roasting events・CROWD ROASTER SHOP: Everything from beans to equipment is readily available

・GPS-linked coffee map function