What is production processing? [Coffee Fanatic Hitomi 's Deep Coffee World Part 1]

Hello, I'm Coffee Fanatic Hitomi .

I usually write about coffee in detail on the Roast Design Coffee blog, but this time I was given the opportunity to write an article for CROWD ROASTER as well (∩´∀`)∩

For the first installment of this series, at the request of CROWD ROASTER , we would like to talk about the production process, which is the method of extracting green coffee beans!

So today, I'll start by talking about production processing!

What is production processing?

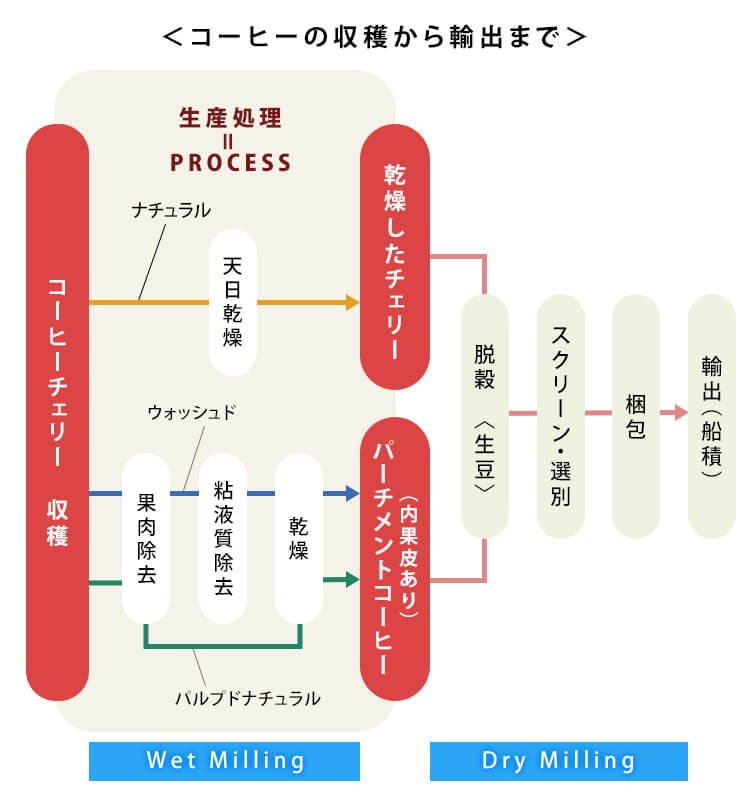

In English it is called PROCESS, and in Japanese it is called "production processing" in the specialty industry. By the way, selection is called Milling (originally meaning "grind"), and the facility where production processing is done is called Wet Mill.

...It's complicated (lol).

In the case of coffee, it is common to extract the seeds (green beans) in some way, rather than the whole fruit, and then roast, grind, and extract the coffee. There are actually methods that use parts other than the seeds (such as giciru and cascara), but since this is a bit outside the scope of this article (just the seeds), I will not go into that here.

There are many reasons why production processing is necessary, but the first and foremost is the need for drying.

If it is not dried, it will rot or mold during storage and transportation, so as a commercial grain, it is essential that it is of stable quality and that it is in a state that allows it to be processed immediately in the consuming country, etc. In the case of coffee, it needs to be in a dried state (moisture content of about 10-11%).

The process of finishing the coffee into dried cherries (fruit) or parchment coffee (coffee with the inner skin still attached) is called wet milling, and this is the role of the so-called “PROCESS.”

...It's complicated (lol).

In the case of coffee, it is common to extract the seeds (green beans) in some way, rather than the whole fruit, and then roast, grind, and extract the coffee. There are actually methods that use parts other than the seeds (such as giciru and cascara), but since this is a bit outside the scope of this article (just the seeds), I will not go into that here.

There are many reasons why production processing is necessary, but the first and foremost is the need for drying.

If it is not dried, it will rot or mold during storage and transportation, so as a commercial grain, it is essential that it is of stable quality and that it is in a state that allows it to be processed immediately in the consuming country, etc. In the case of coffee, it needs to be in a dried state (moisture content of about 10-11%).

The process of finishing the coffee into dried cherries (fruit) or parchment coffee (coffee with the inner skin still attached) is called wet milling, and this is the role of the so-called “PROCESS.”

Dry Mill process after processing

The next step after this is defect removal and screening.

In cherries and parchment coffee, it is impossible to tell if the seeds inside are insect-eaten, underdeveloped, or rotten, because they are covered by the exocarp and endocarp. Therefore, it is necessary to peel off the flesh and endocarp to check whether the seeds are in good condition.

Also, the size of the actual seed may not necessarily be proportional to the size of the coffee cherry itself. The size of the fruit or seed is called the "screen", and if the screen is uneven, the physical properties of the seeds will vary, which will affect not only the taste but also the behavior during roasting.

The dried cherries/parchment brought in after processing are dehulled in a specialized facility, screened, and sorted by specific gravity before being sorted by grade. This process, which determines the quality grade for export, is called grading (export standardization). After this, the cherries are immediately packed in burlap bags and loaded into containers for shipping. This latter process, which is different from the first half of the production processing process, is called dry milling. Basically, the dry mill process is carried out just before export, i.e. just before loading onto the ship.

In cherries and parchment coffee, it is impossible to tell if the seeds inside are insect-eaten, underdeveloped, or rotten, because they are covered by the exocarp and endocarp. Therefore, it is necessary to peel off the flesh and endocarp to check whether the seeds are in good condition.

Also, the size of the actual seed may not necessarily be proportional to the size of the coffee cherry itself. The size of the fruit or seed is called the "screen", and if the screen is uneven, the physical properties of the seeds will vary, which will affect not only the taste but also the behavior during roasting.

The dried cherries/parchment brought in after processing are dehulled in a specialized facility, screened, and sorted by specific gravity before being sorted by grade. This process, which determines the quality grade for export, is called grading (export standardization). After this, the cherries are immediately packed in burlap bags and loaded into containers for shipping. This latter process, which is different from the first half of the production processing process, is called dry milling. Basically, the dry mill process is carried out just before export, i.e. just before loading onto the ship.

Three basic production processes

Dry Milling again deviates from the purpose of this post (;´∀`), so I almost went off topic, but I'd like to get back to the topic of PROCESS (lol).

(Well, the actual name for dry mill is Dry Mill “Process”… thanks for the upload)

There are three main categories of PROCESS, which is the first drying process. Each has its own characteristics in the refining method, as follows.

(Well, the actual name for dry mill is Dry Mill “Process”… thanks for the upload)

There are three main categories of PROCESS, which is the first drying process. Each has its own characteristics in the refining method, as follows.

[3 basic production processes]

① Natural

② Washed

③ Pulped Natural

I'll explain them step by step!!

② Washed

③ Pulped Natural

I'll explain them step by step!!

Natural

Natural is called "non-washing" in Japanese. This is a method in which the harvested coffee cherries are spread out on a concrete patio or a suspended patio (also known as an African bed) and dried in the sun. This is the simplest and easiest drying process, and it is also inexpensive, but when comparing the good and bad points, there are the following aspects.

Pros

・The process is simple and the cost is low. ・It does not require much special equipment (pulp remover, sorting machine, fermentation tank, washing facility, etc.).

Cons

- It takes time to dry (about 4 weeks to 30 days)

・If it rains during drying, fermentation and phenols are more likely to occur. ・As the drying progresses, both unripe green fruits and ripe red fruits turn black, making it impossible to determine the ripeness after drying.

Pros

・The process is simple and the cost is low. ・It does not require much special equipment (pulp remover, sorting machine, fermentation tank, washing facility, etc.).

Cons

- It takes time to dry (about 4 weeks to 30 days)

・If it rains during drying, fermentation and phenols are more likely to occur. ・As the drying progresses, both unripe green fruits and ripe red fruits turn black, making it impossible to determine the ripeness after drying.

Washed

Washed is called the water-washed method. After the flesh is removed with a pulper, the mucilage adhering to the inner skin (parchment) is removed in a fermentation process before being dried.

Pros

- It is dried in parchment form, so the drying time is short (10 days to about 2 weeks).

・The waterway allows for gravity sorting, which allows for screening and quality selection of parchment coffee.

Cons

- It uses a lot of water, so it has a high environmental impact. - It is necessary to dispose of the removed fruit pulp and wastewater.

- Rapid depulping is required (cherries deteriorate over time after harvest), so the farm needs to be close to a wet mill facility.

・If the fermentation process is not handled properly, fermentation defects may occur. ・Water washing equipment is required, so the introduction load is high.

Pros

- It is dried in parchment form, so the drying time is short (10 days to about 2 weeks).

・The waterway allows for gravity sorting, which allows for screening and quality selection of parchment coffee.

Cons

- It uses a lot of water, so it has a high environmental impact. - It is necessary to dispose of the removed fruit pulp and wastewater.

- Rapid depulping is required (cherries deteriorate over time after harvest), so the farm needs to be close to a wet mill facility.

・If the fermentation process is not handled properly, fermentation defects may occur. ・Water washing equipment is required, so the introduction load is high.

Pulped Natural

Pulped Natural is simply called pulped natural. It is a relatively recent production process, and is sometimes called Semi Wash when it first came out. The pulp is removed from the cherries, but the mucilage is not removed before the drying process.

Pros

・It can be dried in a shorter time than Natural (about 2 weeks)

- Uses less water than washed fabrics, making it less environmentally hazardous

Cons

- The removed pulp and wastewater must be disposed of.

・If there is a lot of mucilage, preliminary drying is necessary, which is time-consuming. ・There is a risk of dust and dirt adhering to the mucilage. ・A certain amount of capital investment is required (in some cases, the same as for washed) for equipment such as pulp removers, sorters, and drying tables.

....

So, I've put together a rough list for now!!

In the next issue, I would like to talk about the intention behind each production process being used in the producing countries!

Well then, good day to you all.

Pros

・It can be dried in a shorter time than Natural (about 2 weeks)

- Uses less water than washed fabrics, making it less environmentally hazardous

Cons

- The removed pulp and wastewater must be disposed of.

・If there is a lot of mucilage, preliminary drying is necessary, which is time-consuming. ・There is a risk of dust and dirt adhering to the mucilage. ・A certain amount of capital investment is required (in some cases, the same as for washed) for equipment such as pulp removers, sorters, and drying tables.

....

So, I've put together a rough list for now!!

In the next issue, I would like to talk about the intention behind each production process being used in the producing countries!

Well then, good day to you all.

Fanatic Hitomi

If you want to enjoy coffee more deeply

" CROWD ROASTER APP"

Manabu at CROWD ROASTER LOUNGE

・Push notifications for article updates・Full of original articles exclusive to CROWD ROASTER

・Direct links to detailed information about green beans and roasters

App-only features

- Choose green beans and roasters to create and participate in roasting events・CROWD ROASTER SHOP: Everything from beans to equipment is readily available

・GPS-linked coffee map function

Ryo Mikami

After graduating from Manabu , he worked at Starbucks for some reason, which led him to discover the potential of coffee. After many twists and turns, he joined a specialty coffee trading company. He was enlightened to the way of the fanatic, and is now involved in a wide range of work from commodities to specialties, including market analysis, visiting coffee producing areas, judging competitions, coaching competitions, extraction, roasting, and equipment proposals. He is also an advisor for CROWD ROASTER .

Natural super basics [Coffee Fanatic Hitomi 's Deep Coffee World No. 9]

Free washed fermentation process [Coffee Fanatic Hitomi 's Deep Coffee World Part 6]

Basic flow of flushing method [Coffee Fanatic Hitomi 's Deep Coffee World Part 4]

What is infused coffee? [Coffee Fanatic Hitomi 's Deep Coffee World No. 18]

What is the Costa Rican Anaerobic Honey Process? [Coffee Fanatic Hitomi 's Deep Coffee World No. 17]

What is the difference between yellow, gold, and black? Costa Rican Honey Process [Coffee Fanatic Hitomi 's Deep Coffee World No. 16]