Free washed fermentation process part 2 [Coffee Fanatic Hitomi 's Deep Coffee World No. 7]

Hello! I'm Coffee Fanatic Hitomi .

Production processing series. I would like to continue explaining the water-washing type Free Washed (Fully Washed)!

Click here for the previous article

Last time we talked about the differences in fermentation (wet and dry fermentation), but from point ③ onwards we will introduce applied patterns.

Last time we talked about the differences in fermentation (wet and dry fermentation), but from point ③ onwards we will introduce applied patterns.

[Continued] Variations of Fully Washed

③ Fermented twice in outdoor concrete tanks (Soaking = Double Fully Washed)

④ Yeast fermentation in outdoor concrete tanks using yeast spraying

⑤ Cold fermentation in indoor concrete tanks using air conditioning

Just looking at the words doesn't really make much sense!! (laughs)

Well, let's go!

Second water wash "Soaking"

This is what is known as the "Kenyan method," but Fanatic has never heard of it by that name overseas... However, it is a common production processing method in Central and East Africa, including Kenya.

Soak means to rinse in English, and is the same as rinsing. After fermentation, the parchment is returned to the tank and submerged in plenty of water. This lasts for about 24 hours.

Well, since the fermentation has already finished once, I don't think you need to leave it for that long, maybe 48 hours at most?

Since it is washed twice, it is also called Double Fully Washed (DFW).

The water during soaking is so clean ♡ @ Costa Rica

Soaking tank at El Injerto, Guatemala

By the way, this is what the taste will be like after soaking.

The acidity is more rounded and the texture is smoother. The clean cup is improved.

...

Basically, I don't think there are any negative aspects to soaking. It is said that the flavor of green beans with little potential will be diluted, but the clean cup will increase and the texture will improve. However, the acid structure will become somewhat rounded, so it may not feel as fresh.

Although it is a fermentation process because it is soaked in water, it is not really used for that purpose. It is more like a thorough cleaning. However, some fermentation should be progressing slightly, so perhaps lactic acid bacteria are somewhat dominant. I don't know... Personally, it is one of my favorite production processes.

Since soaking is a process that takes place after the fermentation process, the flavor will tend to change slightly depending on how the previous fermentation process went.

Basically, I don't think there are any negative aspects to soaking. It is said that the flavor of green beans with little potential will be diluted, but the clean cup will increase and the texture will improve. However, the acid structure will become somewhat rounded, so it may not feel as fresh.

Although it is a fermentation process because it is soaked in water, it is not really used for that purpose. It is more like a thorough cleaning. However, some fermentation should be progressing slightly, so perhaps lactic acid bacteria are somewhat dominant. I don't know... Personally, it is one of my favorite production processes.

Since soaking is a process that takes place after the fermentation process, the flavor will tend to change slightly depending on how the previous fermentation process went.

The basis is wet fertilization, but if there is not an abundant water source, a lot of water will be used (double (;´・ω・)), so I think that more and more places are using dry fertilization.

Even in Rwanda, many CWSs dry ferment before soaking.

[Water fermentation + soaking]

The acidity is bright and mellow. The texture is smooth and slightly full-bodied.

[Dry fermentation + soaking]

The basic tendency is the same as above. Sweetness and body are slightly stronger.

....

By the way, it's a little difficult to tell the difference between the two just by looking at them, but I think there will be a slight difference.

The appearance of soaked green beans is very beautiful. However, because they are exposed to water for a long period of time, they will deteriorate if not carefully dried afterwards, so moisture management is important.

[Water fermentation + soaking]

The acidity is bright and mellow. The texture is smooth and slightly full-bodied.

[Dry fermentation + soaking]

The basic tendency is the same as above. Sweetness and body are slightly stronger.

....

By the way, it's a little difficult to tell the difference between the two just by looking at them, but I think there will be a slight difference.

The appearance of soaked green beans is very beautiful. However, because they are exposed to water for a long period of time, they will deteriorate if not carefully dried afterwards, so moisture management is important.

In Kenya, they dry the plants on raised African beds, which allows for very clean and efficient drying (although this is based on drying efficiency, and workability is not so good). Tanzania also uses African beds, but perhaps because the drying is not as thorough, there are many cases where the plants have turned white compared to Kenya, and they tend to wither and die easily.

(Left) Kenya's DFW (Right) El Salvador's DFW... both look beautiful♡

(I can't tell Shin the photo, but El Salvador has a slightly higher proportion of silver skin.)

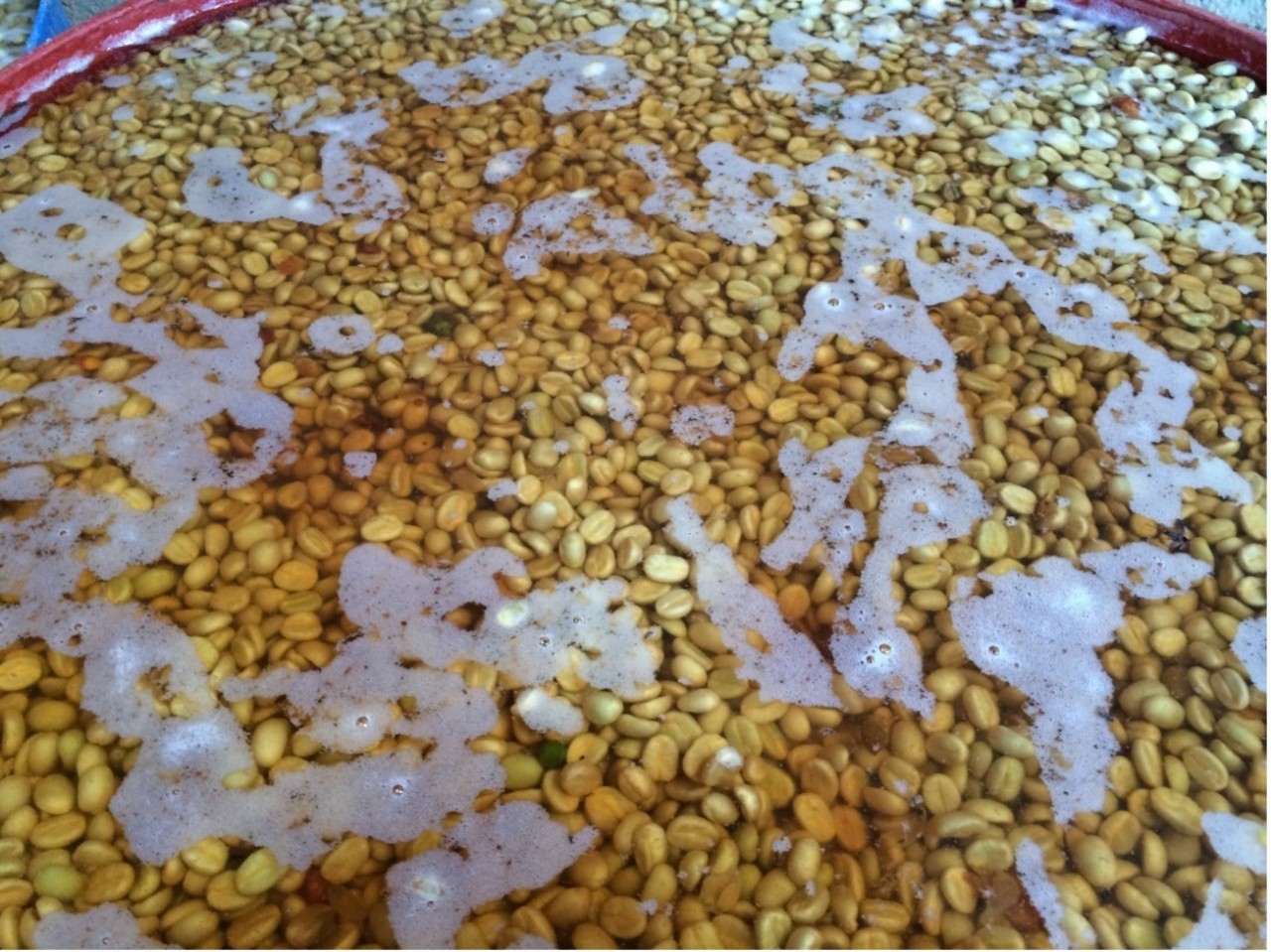

"Yeast Fermentation" for antibacterial purposes

Yeast is sprinkled on during tank fermentation. This yeast fermentation method is said to be the recommended method by Professor Manabu of Lavras University in Brazil, but can also be seen in Burundi, Rwanda, and other countries.

Yeast is a Shin used in the alcoholic fermentation of bread, beer, etc., and has anaerobic characteristics (it can be active even in the absence of oxygen). In normal fermentation, it is left to nature, so frankly speaking, it is not at all clear what types of fungi are active and in what proportions they are fermenting the mucilage (*´ω`*).

The use of yeast at least has no negative effect on fermentation, reducing the proportion of undesirable bacteria. The alcohol produced also contributes to the quality stability. During fermentation, a film of foam is formed on the surface of the fermentation tank, which helps to make the fermentation process more uniform.

It is often thought that this is for flavor, but in the case of washed beer , yeast fermentation is carried out mostly for the purpose of suppressing bacteria. So, basically, no flavor is added, but sometimes a sweet nuance reminiscent of bread during fermentation comes out (it's really faint...).

It is often thought that this is for flavor, but in the case of washed beer , yeast fermentation is carried out mostly for the purpose of suppressing bacteria. So, basically, no flavor is added, but sometimes a sweet nuance reminiscent of bread during fermentation comes out (it's really faint...).

It is also used in natural anaerobic fermentation, but it does not impart any yeast-derived flavors.

Wet fermentation is the mainstream method of yeast fermentation. Dry fermentation requires stirring a large amount of parchment to distribute the bacteria, which is a lot of work. As for the taste...

Wet fermentation is the mainstream method of yeast fermentation. Dry fermentation requires stirring a large amount of parchment to distribute the bacteria, which is a lot of work. As for the taste...

It imparts a subtle sweetness and slightly improves the volume of the texture.

I once participated in a test with a batch from Rwanda. I think the effect is similar to soaking, but since soaking is almost the default in African countries, it's hard to judge the effect of the yeast alone. However, there was a difference in sweetness, texture, and sharpness of acidity with and without yeast (it's a really subtle difference, but...), so I think there is some effect.

For now, it is a useful fermentation method for suppressing bacteria, improving quality, and reducing the risk of damage from phenols and other substances.

Temperature-controlled fermentation (Cold Fermentation)

I wasn't sure of the proper term, so I decided to use the term cold fermentation. It's basically fermentation at a controlled temperature.

In the past, Nicaraguan producers fermented their mucilage indoors in climate-controlled rooms rather than outdoors, with the room temperature set at around 20°C.

In the past, Nicaraguan producers fermented their mucilage indoors in climate-controlled rooms rather than outdoors, with the room temperature set at around 20°C.

The temperature in producing areas rises quite a bit during the day, but it generally drops considerably at night, so if you can control the temperature from 2 pm until the evening, air conditioning costs may not be that high.

Nicaragua Casa Blanca's indoor fermentation tanks (the black pipes on the side connect to the piñarense system behind the wall)

This method does not raise the temperature much during fermentation, so the fermentation time is longer. However, it also reduces strange spoilage and contamination by foreign bacteria.

The flavor is a little vague due to the long fermentation time, but the quality is stable. So, what about the taste...?

The texture becomes smoother. On the other hand, the acidity and flavor become milder.

Roughly speaking, it gives a "calm" feeling in all respects. As with soaking, it seems that the longer the time spent in the aquarium, the stronger the body tends to become and the smoother it becomes.

Dry fermentation is fine if the air is controlled, but the temperature of the fermenting parchment will continue to rise, so it is easier to keep the temperature low with a fermentation method that uses water.

In addition, production processing is started at night before this, and preliminary temperature adjustments are also made, such as showering the cherries with water after harvest to maintain a low temperature (I think they call it a cold shower... (;・∀・)).

Well, like wine, beer, and other fermentation, temperature control is the norm. This is because the quality of the resulting product can vary greatly (failure = spoilage). So, there seems to be a growing trend among producers recently to want to control the temperature during fermentation.

In particular, with Funky Natural and anaerobic fermentation products, as the temperature rises, the strawberry flavor goes straight through to soy sauce and miso flavor (lol), so temperature control is really important!

There are some special batches out there that claim to have a longer fermentation time after adding microorganisms, such as 48 hours, 92 hours, or 30 days, but it's not necessarily true that the longer the fermentation time, the better. If the clean cup drops and the fermentation smell becomes dominant, it's pointless, so I think it will continue to be important to continue to carefully manage the product.

....

So, I've quickly introduced three types!

Next up will be mechanical wash!

Well, good day everyone.

....

So, I've quickly introduced three types!

Next up will be mechanical wash!

Well, good day everyone.

2023.07.29

Fanatic Hitomi

Fanatic Hitomi

If you want to enjoy coffee more deeply

" CROWD ROASTER APP"

Manabu at CROWD ROASTER LOUNGE

・Push notifications for article updates・Full of original articles exclusive to CROWD ROASTER

・Direct links to detailed information about green beans and roasters

App-only features

- Choose green beans and roasters to create and participate in roasting events・CROWD ROASTER SHOP: Everything from beans to equipment is readily available

・GPS-linked coffee map function

Ryo Mikami

After graduating from Manabu , he worked at Starbucks for some reason, which led him to discover the potential of coffee. After many twists and turns, he joined a specialty coffee trading company. He was enlightened to the way of the fanatic, and is now involved in a wide range of work from commodities to specialties, including market analysis, visiting coffee producing areas, judging competitions, coaching competitions, extraction, roasting, and equipment proposals. He is also an advisor for CROWD ROASTER .

Natural super basics [Coffee Fanatic Hitomi 's Deep Coffee World No. 9]

Free washed fermentation process [Coffee Fanatic Hitomi 's Deep Coffee World Part 6]

Basic flow of flushing method [Coffee Fanatic Hitomi 's Deep Coffee World Part 4]

What is production processing? [Coffee Fanatic Hitomi 's Deep Coffee World Part 1]

What is infused coffee? [Coffee Fanatic Hitomi 's Deep Coffee World No. 18]

What is the Costa Rican Anaerobic Honey Process? [Coffee Fanatic Hitomi 's Deep Coffee World No. 17]