Hello! ! Coffee Fanatic Hitomi ! !

From the last time , we started talking about natural production processing.

Now that I have given a rough explanation of the workflow, I would like to move on to talk about specialty grade natural products! !

Natural is a simple yet profound production process, and if you compare it to wine, it can be said to be similar to red wine.

In the past, coffee cherry pulp and fermented odors were forbidden in the industry, but in recent years, it can be said that these flavors are being actively utilized! !

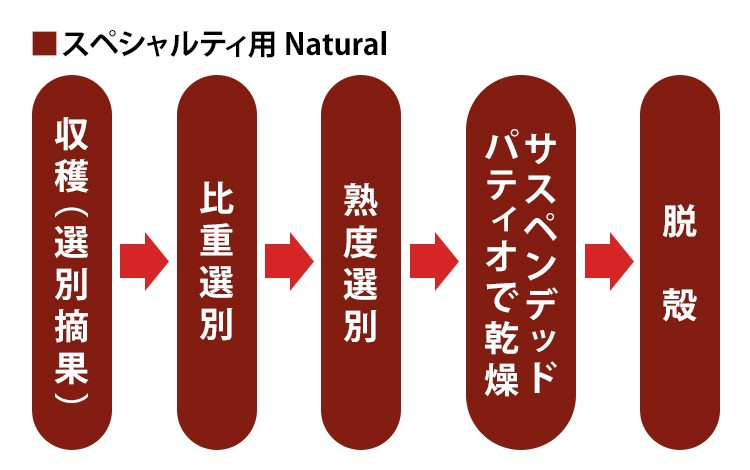

The specialty grade natural flow that I introduced last time was as follows, but today I would like to focus on the “non-fermented” type first! !

From the last time , we started talking about natural production processing.

Now that I have given a rough explanation of the workflow, I would like to move on to talk about specialty grade natural products! !

Natural is a simple yet profound production process, and if you compare it to wine, it can be said to be similar to red wine.

In the past, coffee cherry pulp and fermented odors were forbidden in the industry, but in recent years, it can be said that these flavors are being actively utilized! !

The specialty grade natural flow that I introduced last time was as follows, but today I would like to focus on the “non-fermented” type first! !

[Natural process in specialty]

Specialty Grade Natural Process

It is sweet, full-bodied, and natural with a rich impression, but there are two concerns in the production process: (1) It takes a long time to dry, and (2) If ripeness is not sorted first, it will be impossible to tell in the latter stages of the process. It's a point. However, there is nothing we can do about the time it takes for drying in step 1, so the ripeness factor in step 2 is very important.

【harvest】

In producing countries other than Brazil, fruit is basically hand-picked, but in order to produce good natural fruit, it is most important to perform selective picking. Harvesting is carried out by local grower communities and temporary workers (Indians) who travel throughout Central America.

A skilled picker can harvest about 60 kg of fruit in a day, but selective picking reduces the yield. In addition, it is necessary to pay extra wages after receiving proper training on how to judge proficiency, so it is actually quite a difficult hurdle from the beginning.

Since the basic commission system is used, harvesters are inevitably tempted to increase the quantity. It's important to closely supervise this and train them to pick at the right ripeness... Some wealthy and well-established farms will lend goggles and gloves to the harvesters, but for the most part, everyone does it barehanded.

By the way, highly ripe cherries can be easily removed from the side branches without having to use much force. At that time, no axis remains on the actual side. Conversely, even if the fruit is red, if the stem remains, it can be said that the fruit is not fully ripe. In terms of color, a deep reddish-purple is preferable.

A skilled picker can harvest about 60 kg of fruit in a day, but selective picking reduces the yield. In addition, it is necessary to pay extra wages after receiving proper training on how to judge proficiency, so it is actually quite a difficult hurdle from the beginning.

Since the basic commission system is used, harvesters are inevitably tempted to increase the quantity. It's important to closely supervise this and train them to pick at the right ripeness... Some wealthy and well-established farms will lend goggles and gloves to the harvesters, but for the most part, everyone does it barehanded.

By the way, highly ripe cherries can be easily removed from the side branches without having to use much force. At that time, no axis remains on the actual side. Conversely, even if the fruit is red, if the stem remains, it can be said that the fruit is not fully ripe. In terms of color, a deep reddish-purple is preferable.

This color is called cow blood in Central America and other countries, and is used as a guideline for determining color during harvest.

In the case of Brazil, it is not possible to pick by hand, so we reduce the output of the harvesting machine so that we can harvest fruits that are easy to remove with as little force as possible, which means they are highly ripe.

In the case of Brazil, it is not possible to pick by hand, so we reduce the output of the harvesting machine so that we can harvest fruits that are easy to remove with as little force as possible, which means they are highly ripe.

[Specific gravity selection]

After harvesting, fruits are sorted by specific gravity using a water tank. Here, overripe fruits, impurities such as leaves and branches, and poorly grown fruits are removed. Even if the fruit looks ripe and looks reddish, the green beans inside may not be fully grown or may be eaten by insects.

These disadvantageous fruits will float to the surface when placed in an aquarium, and heavy fruits will sink because they have a higher specific gravity than water. In Africa and other countries, regulations require that cherries be used in an aquarium before being delivered to a processing plant.

These disadvantageous fruits will float to the surface when placed in an aquarium, and heavy fruits will sink because they have a higher specific gravity than water. In Africa and other countries, regulations require that cherries be used in an aquarium before being delivered to a processing plant.

It should be noted that the green fruits that are less ripe also have a higher specific gravity, so they will sink to the bottom of the aquarium. Even if you harvest the fruit, the green fruit has to be removed in the subsequent process, so in the end, your commission rate will be poor. That's why the first picking is so important.

In the case of Brazil, specific gravity sorting is done mechanically using a system that uses a siphon such as Piñarense.

In the case of Brazil, specific gravity sorting is done mechanically using a system that uses a siphon such as Piñarense.

[Ripeness selection]

After the cherries have been sorted by specific gravity, they are then visually sorted for ripeness. In Africa, there is a hand-picked patio near the desk where cherries are handed in, where growers manually pluck less-ripe cherries.

In the case of Central America, pickers and workers (farm employees) may handpick the produce at the production processing facility. Since heavy blue fruit cannot be completely removed by gravity sorting, this is the final stage for determining ripeness. After this point, sorting until the dry mill process becomes almost impossible.

In Brazil, ripeness may be determined using a color-difference sorter.

In Brazil, ripeness may be determined using a color-difference sorter.

[Drying on suspended patio]

Normal naturals are left on concrete patios, but specialty grades are dried on raised drying racks with good ventilation. These drying racks are so common in Africa that they are commonly referred to as African Beds, but their official name is Suspended Patios.

With concrete, the surface tends to get hot, so drying will be a little rough. Suspended patios are laid out on mesh, allowing drying to be carried out above and below the shelves, making drying more efficient and in good conditions. Furthermore, there are various ideas such as providing sunlight above the drying table (Shade) or covering the drying table like a plastic greenhouse (Secadora).

With concrete, the surface tends to get hot, so drying will be a little rough. Suspended patios are laid out on mesh, allowing drying to be carried out above and below the shelves, making drying more efficient and in good conditions. Furthermore, there are various ideas such as providing sunlight above the drying table (Shade) or covering the drying table like a plastic greenhouse (Secadora).

Suspended Patio (In the case of this farm, the bottom vinyl is not mesh)

By the way, if you install a shade, it will take longer to dry because it blocks sunlight, and if you use a Secadora greenhouse, it will dry in a hot and humid environment.

Secadora greenhouse (Washed parchment is dried here)

If possible, I would like to hand-pick abnormal fruits even while they are drying, but as you can see, as they dry, they all turn black, making it almost impossible to sort them out.

In the case of Brazil, the lots are large, so we rarely use suspended patios for drying. Although it is covered a little with vinyl, it is basically dry concrete ground.

In the case of Brazil, the lots are large, so we rarely use suspended patios for drying. Although it is covered a little with vinyl, it is basically dry concrete ground.

[Threshing with dry mill]

After drying, the cherries are left as they are for resting. Once the sale of the coffee has been finalized and shipping has been decided, the coffee is threshed immediately before the final sorting process and grading, which is export standardization, begins.

In the case of natural products, this final Dry Mill sorting is quite important. No matter how many cherries are sorted for quality, you won't know what's inside until you crack open the fruit.

In the case of natural products, this final Dry Mill sorting is quite important. No matter how many cherries are sorted for quality, you won't know what's inside until you crack open the fruit.

In addition, the removed pulp has more dust and dirt than washed parchment, so it also creates a lot of dust. If you don't manage it properly, you'll end up with green beans that are full of dust and silver skin.

In dry mills, the final specific gravity sorting is performed using a specific gravity sorter with a slope, and the quality is determined by the degree of inclination, output, and position of the outlet (the higher the position, the fresher the beans will be). will change.

In dry mills, the final specific gravity sorting is performed using a specific gravity sorter with a slope, and the quality is determined by the degree of inclination, output, and position of the outlet (the higher the position, the fresher the beans will be). will change.

Dry mill specific gravity sorter

Finally, we use a color-difference sorting machine (such as one made by Satake) and a final visual check to hand-pick.

・・・・・・・・・

The above is how to make specialty grade natural products.

Well, to be honest, it is quite difficult to properly manage everything so it is difficult to completely cover all of the above, but the natural, which is described as Costa Rica's "Black Shin ", is made using the process introduced above. We do it carefully.

A simple, yet very special natural process...

Next time, we will take a look at the more complicated fermentation system! !

・・・・・・

Hello everyone.

・・・・・・・・・

The above is how to make specialty grade natural products.

Well, to be honest, it is quite difficult to properly manage everything so it is difficult to completely cover all of the above, but the natural, which is described as Costa Rica's "Black Shin ", is made using the process introduced above. We do it carefully.

A simple, yet very special natural process...

Next time, we will take a look at the more complicated fermentation system! !

・・・・・・

Hello everyone.

2023.9.15

Fanatic Hitomi